*The manual will be periodically updated if needed.

◆ Product video (360° view)

https://www.youtube.com/watch?v=x2wjR95Dt90

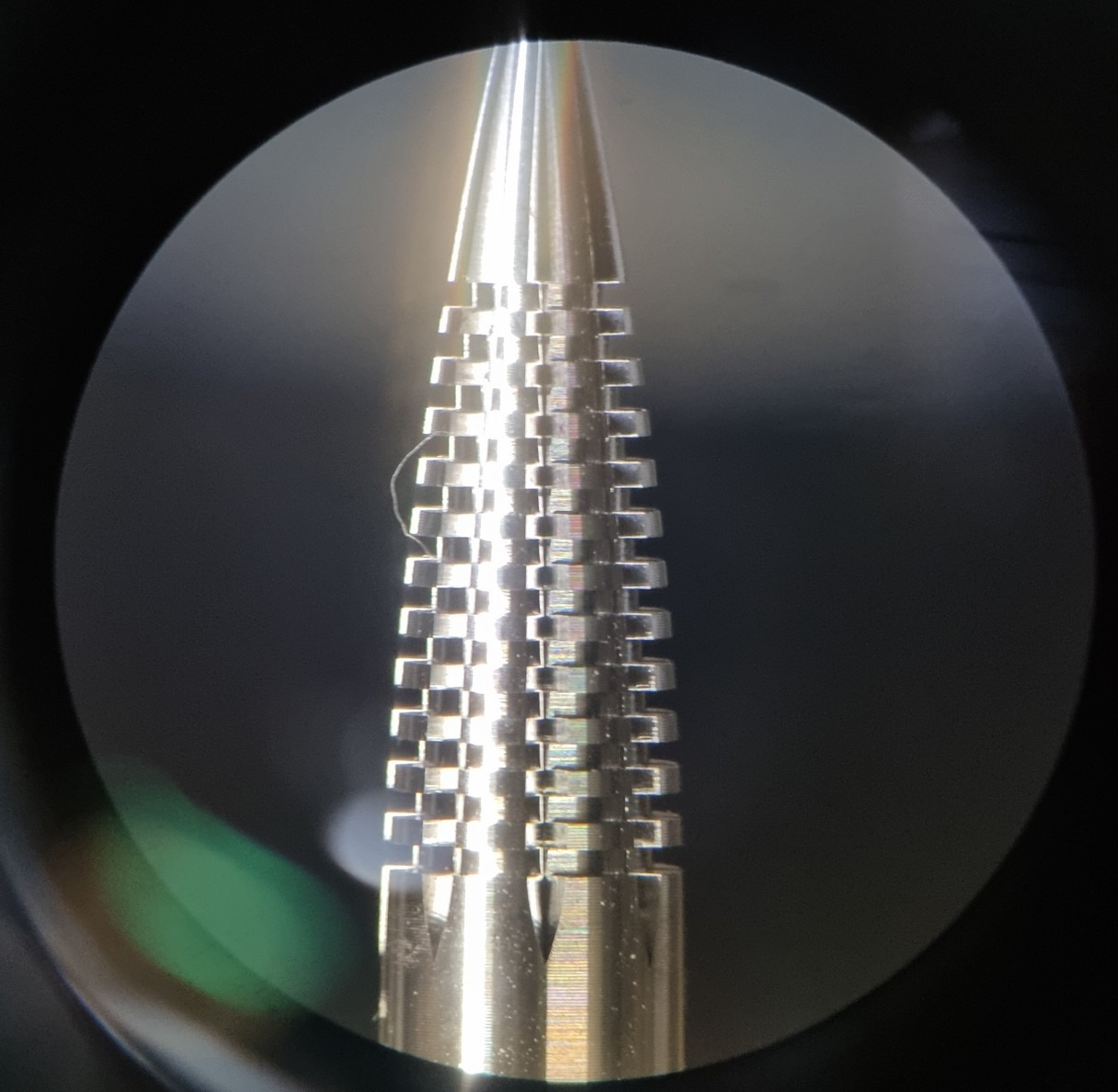

◆ Product name: Eureka Slim Titanium Dip Pen Nib

◆ Material:

Titanium alloy Grade 23 ( = Grade 5 ELI ) / Material Origin: Germany

"Extra low interstitial" (ELI) refers to a grade of titanium alloy, specifically Ti-6Al-4V (Grade 5) ELI, where "ELI" stands for "Extra Low Interstitials". This designation indicates a version of the standard Ti-6Al-4V alloy with significantly reduced levels of interstitial elements like oxygen, nitrogen, and carbon.

The reduced interstitial content results in improved ductility, fracture toughness, and biocompatibility, making it suitable for demanding applications.

◆ Initially the nib may feel slightly scratchy. This is because the nib isn't polished too smoothly during the production process. According to Eureka's research, too much polishing can lead to ink skipping. As you use the pen, the scratchiness will decrease. Everytime you pick up the pen to use it, the rotation angle will be random. So the nib will wear evenly. However, if you are using it on prolonged periods (wearing down just one spot), please change the angle occasionally.

◆ Example Photos

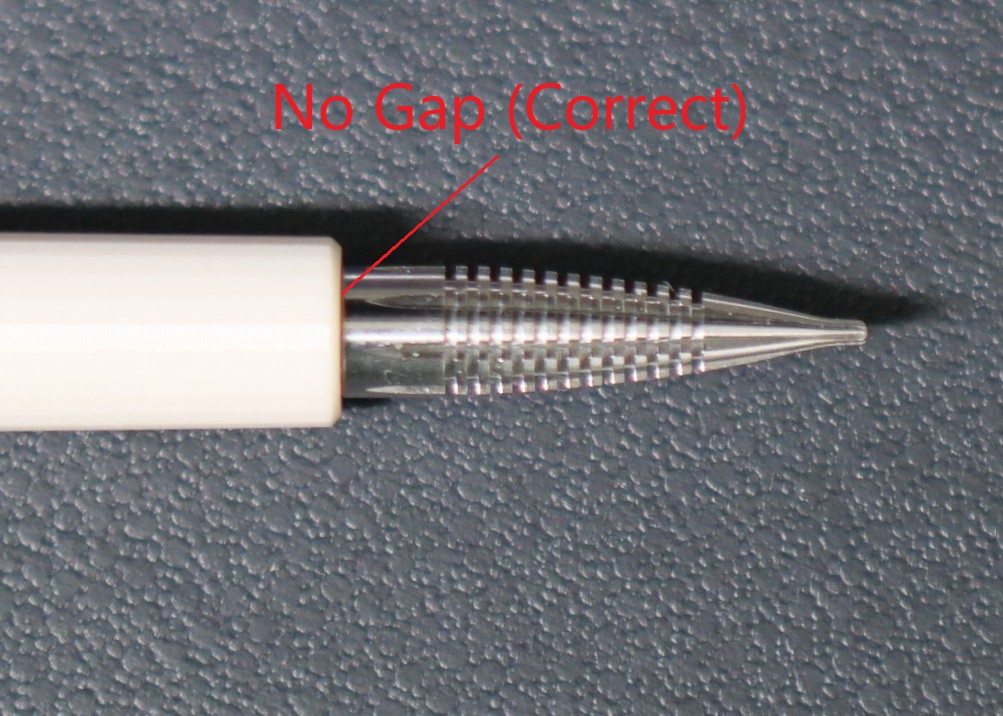

◆ How to install the nib into the Eureka dip pen barrel:

1) Push the nib in all the way, while keeping the nib & barrel straight (1st picture)

2) Thread on the nib (rotate clockwise)

* If you feel the thread is getting stuck, unscrew the nib a bit (counterclockwise) and try again.

* If you feel the thread is getting stuck, do not forcefully install the nib (thread can be damaged).

3) Once the nib is installed, there shouldn't be any gap between the nib and the barrel (2nd picture)

* If there's a gap between the nib & barrel, the nib can wobble a bit. Please thread in all the way.

4) 3rd picture shows the correct installation with no gap. The nib will not wobble at all.

◆ How to use the dip pen nib (+ some tricks) :

1) direct dip into ink bottle

2) filling up a small spoid, then applying ink to the "fin" grooves

* you can fill several small spoids with different ink colors. then mix them directly into the grooves for gradient color effect, or mixed ink color effect.

* the ink in the spoid doesn't dry out fast. you can keep it in there for a long time.

* get the small spoid (2ml) with a small opening so the ink doesn't dry out fast.

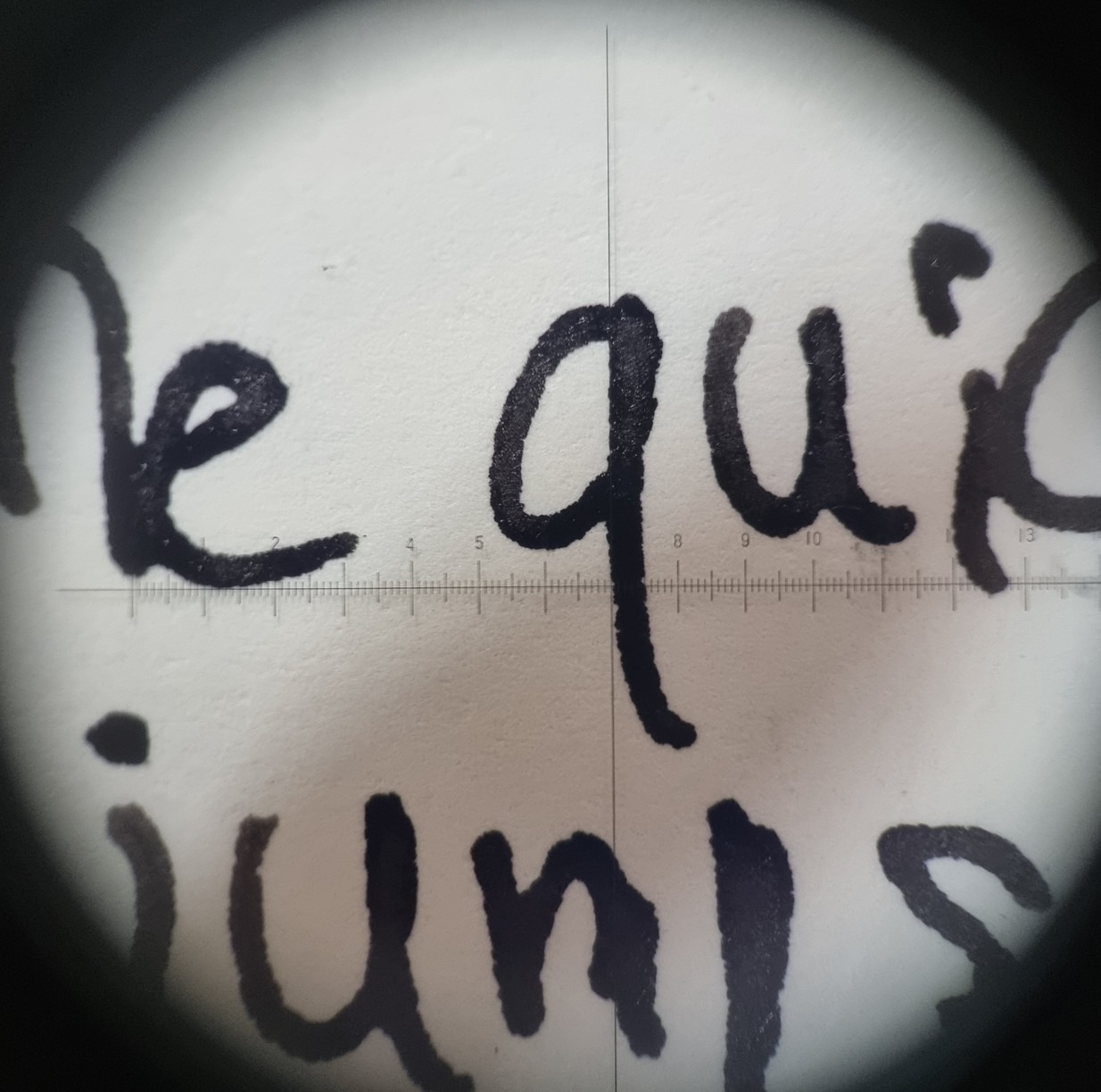

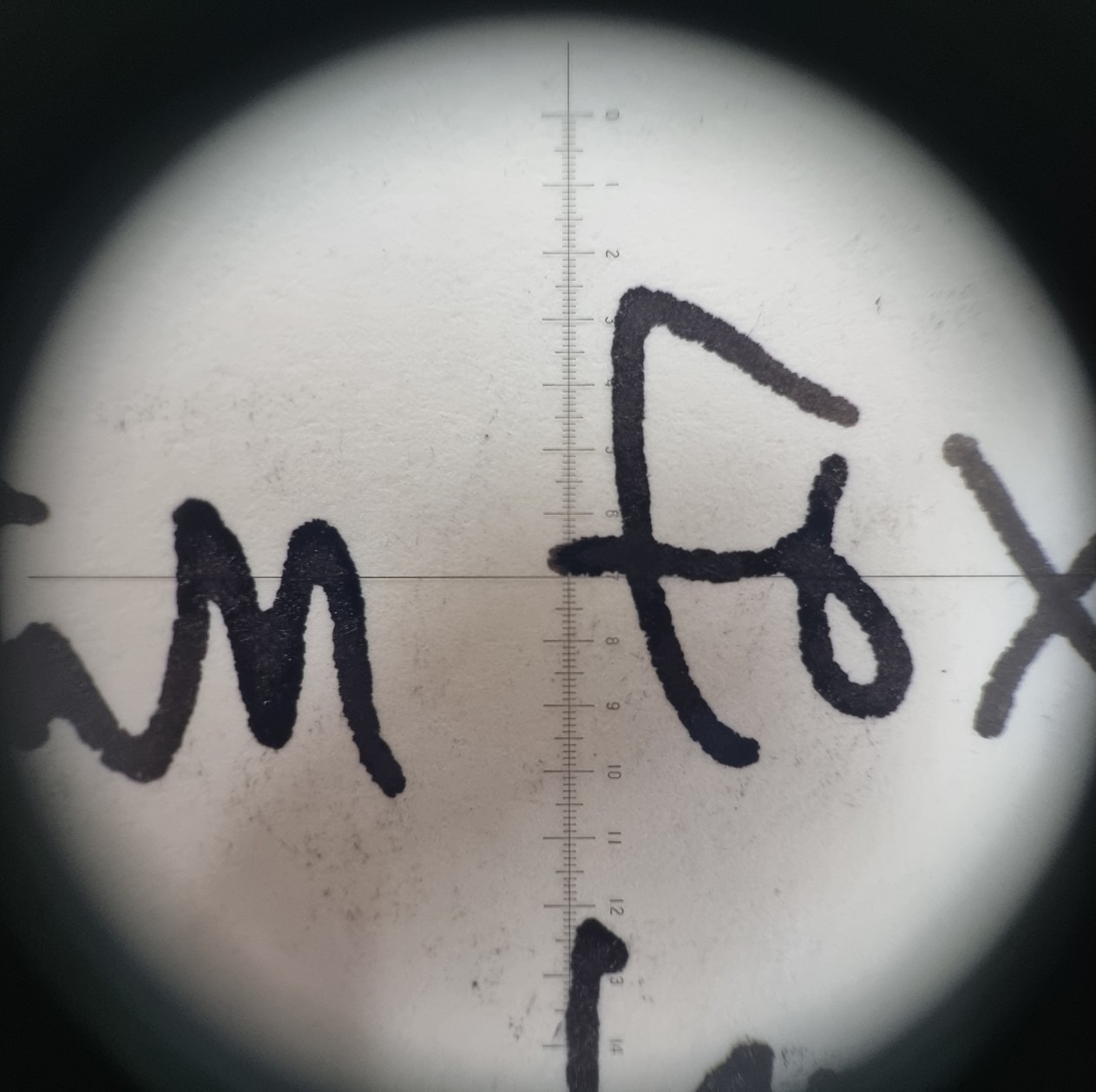

◆ Effective nib point length : 2mm (similar thickness will be maintained)

* maximum nib point length : 2~4mm (thickness will be altered a lot, functionality will decrease)

titanium alloy hardness: approx. Moh 6~6.5

* typical "iridium-point" hardness: about Moh 6.5~7.5. Really hard ones estimated to be Moh 7.5+

* stainless steel = ~6 / iridium = 6.5 / osmium = 7 / tungsten = 7.5 / hardened steel = 7~8 / tungsten carbide = 9 / diamond = 10

◆ Ink type recommendations: to be updated

◆ Custom installation examples (Using / modifying existing pen models of various brands)

If the hole is too big, roll Kapton, masking, or typical tape, etc onto the thread. You will have to check frequently for the right amount of tape used. Then simply rotate + push into the hole (friction fit).

If the hole is too small, you may have to cut / grind the barrel opening to make the hole bigger.

◆ DIY Barrel: You can make your own barrel. select and purchase wooden or plastic rod from your local supplier. drill a hole sized 3.7~3.8mm (depth 6~8mm). then screw on the nib forcefully while maintaining straight angle (wear a glove if necessary). This will form a thread to the hole you've drilled.

Or you can drill a oversized hole, then roll Kapton, masking, or typical tape, etc onto the thread. You will have to check frequently for the right amount of tape used. Then simply rotate + push into the hole (friction fit). Please see the 5th picture, you can see the yellow masking tape. Masking tape will provide cushiony (flex) feel due to the softness of the material. Kapton / typical tape is harder, so there will be less cushion effect. Masking tape may feel a bit soggy, but it's up to your preference.

◆ Nib writing thickness: Approximately 0.5~0.8mm

*Line thickness can vary depending on the following factors:

1. writing speed

2. nib wear state

3. if the ink is fully filled, initially the line will be thicker (will return to normal thickness as the ink is used)

4. if the ink is running very low, the line will be thinner than usual.

◆ How to regrind the dip pen nib: to be updated

◆ Dip Pen Nib Maintenance Guide

To ensure the longevity of your nib and maintain optimal ink flow, please follow these cleaning procedures:

1) Immediate Rinse: Directly after use, rinse the nib in clean water to prevent ink from drying out.

2) Removal of Dried Ink: If ink residue has begun to harden, place the nib under flowing tap water and scrub the grooves using a fine-bristle toothbrush.

3) Deep Cleaning: In worst cases of heavy buildup or stubborn residue, utilize an ultrasonic cleaner for a thorough cleaning.