Polyetheretherketone (PEEK) is a high performance thermoplastic utilized extensively in semiconductor manufacturing, medical device production, and extreme environments where conventional polymers fail to maintain structural integrity.

◆ Characteristics of PEEK

As a premier engineering plastic, PEEK offers a distinct set of performance advantages:

1) Chemical Inertness: Exceptional resistance to acids, alcohols, acetone, and various harsh industrial solvents.

2) Thermal Stability: Maintains a maximum continuous operating temperature of 260°C, whereas general purpose plastics often undergo thermal distortion below 120°C.

3) Mechanical Integrity: Provides superior tensile strength, wear resistance, and long-term durability that significantly exceeds standard commercial resins.

◆ Comparative Value in Fine Instruments

Traditional fountain pens are typically manufactured using general purpose resins such as ABS, Acrylic (Plexiglass / PMMA), Polycarbonate (PC), Polypropylene (PP), or Epoxy.

PEEK vastly outperforms these materials in every technical category; however, the acquisition cost for high-quality PEEK is high.

PEEK is significantly more expensive than acrylic (Plexiglass / PMMA), often costing approximately 30 times more per kilogram.

Material Price Range (USD/kg) Standard Grade (Per Kg):

- Acrylic $1.50 - $5.00

- PEEK $100 (German import)

◆ Resistant to Ink Stains

PEEK stands as a premier high-performance polymer due to its exceptional chemical resistance, allowing it to resist permanent ink staining even under extreme conditions.

Unlike general resins such as ABS, polycarbonate, or polystyrene which suffer from crazing, clouding, or total melting when exposed to harsh solvents, PEEK remains structurally and visually unaffected by acetone.

This unique stability enables users to utilize aggressive cleaning agents to strip away deep pigments without compromising the material's integrity, whereas standard plastics would undergo irreversible solvation or surface degradation.

◆ Material Sourcing and Precision Engineering

To ensure the highest standards of precision and reliability, only German sourced PEEK is utilized for primary components, intentionally excluding lower-grade alternatives.

Precision machining firms frequently avoid substandard materials due to inconsistent performance during fabrication. While such materials may superficially resemble high-grade PEEK, they may exhibit "gumming" or melting behaviors during the machining process. This inconsistency compromises dimensional accuracy and surface finish.

Under identical processing parameters, German PEEK maintains its structural properties, allowing for the tight tolerances required in high-end manufacturing. Utilizing premium grade material mitigates the risk of catastrophic material failure and ensures that no compromises are made regarding the quality of the final product.

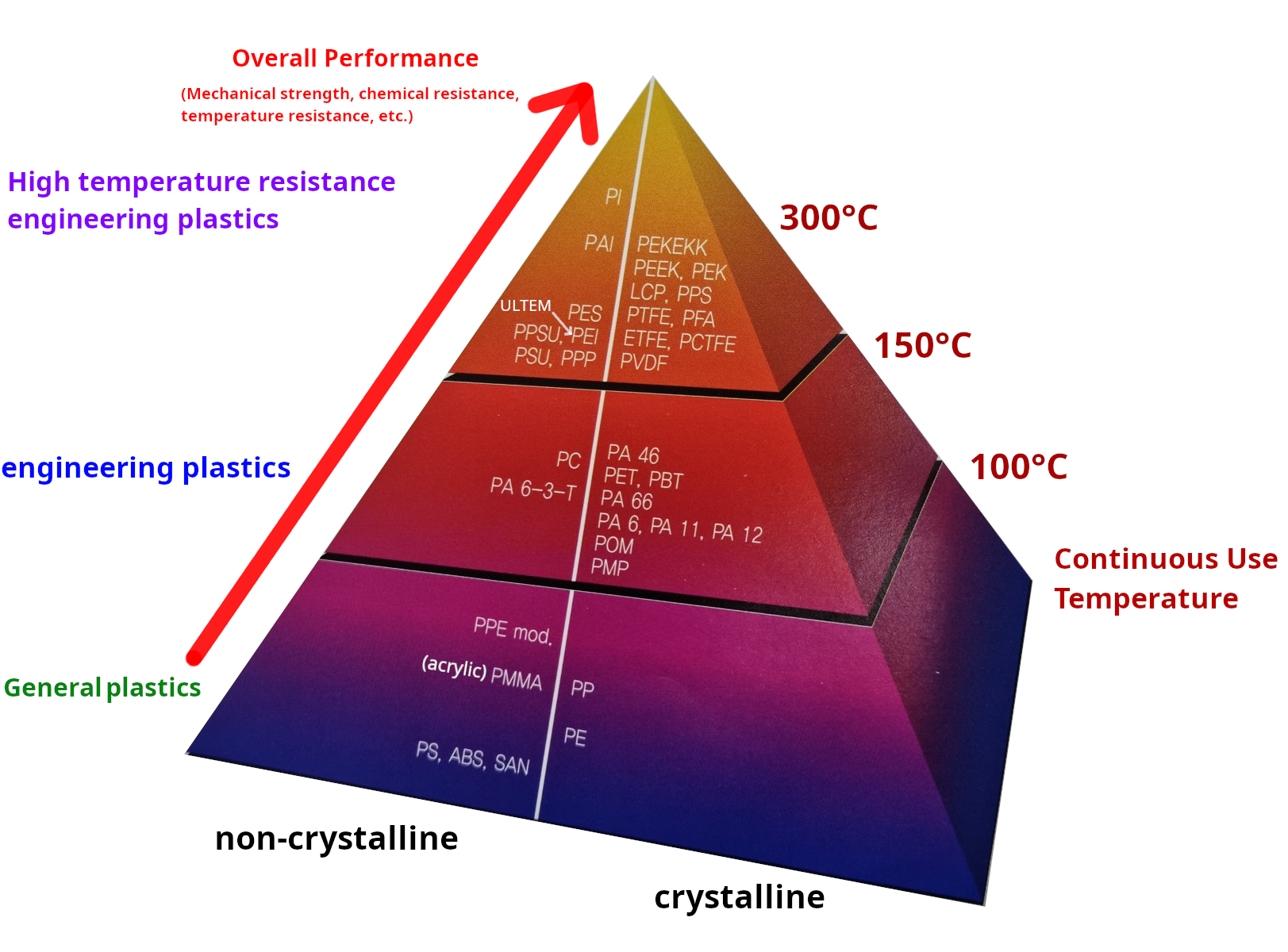

----- Plastics Pyramid Chart (by Overall Performance) -----