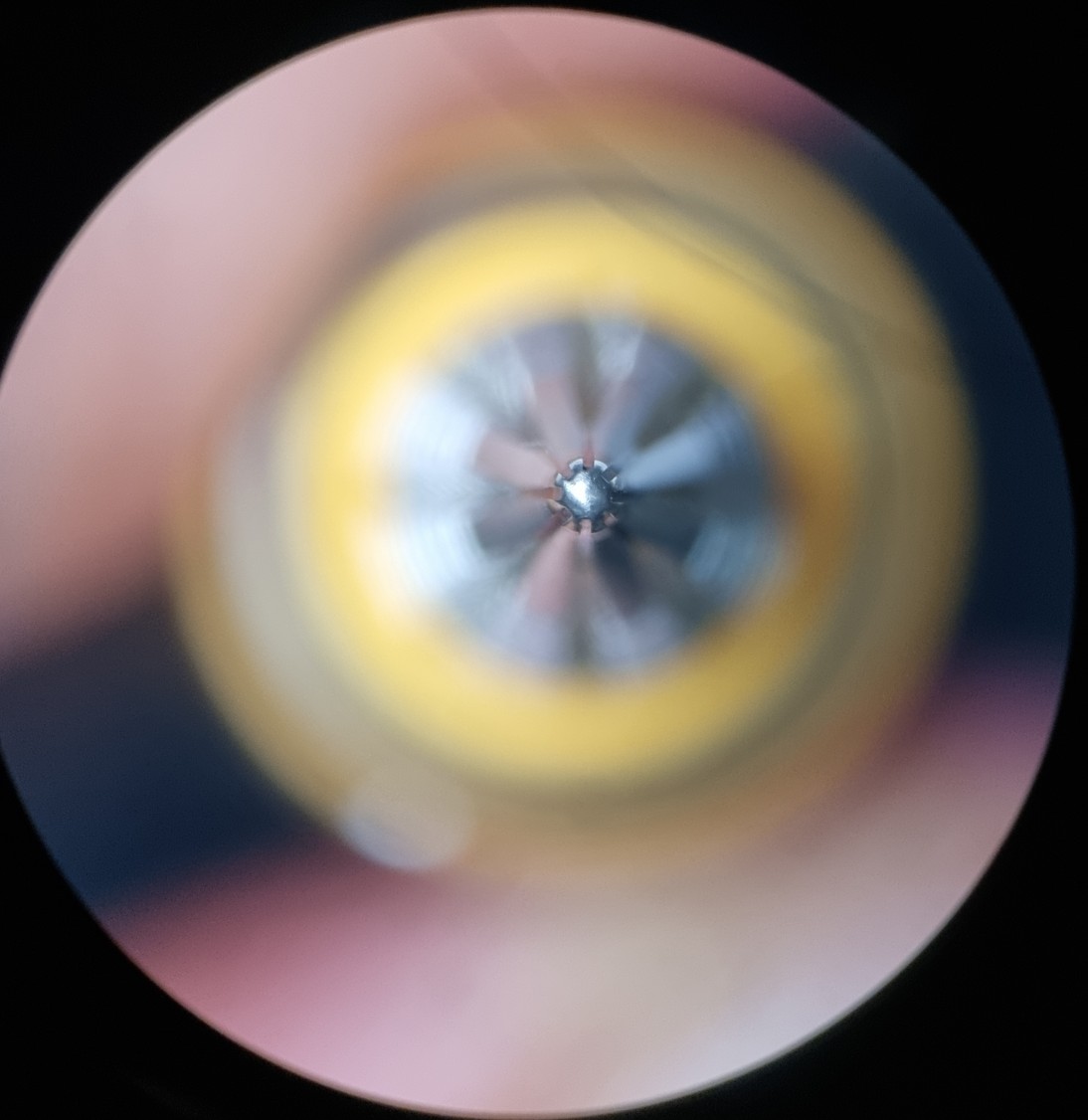

Dip pen nib (slim type / "oriental brush(OB)" design) has been developed.

After final analysis and calibration, production of this specific model will be initiated.

initially slim type will be developed (oriental brush design), followed by thicker and bigger "standard" type.

waterdrop design may be developed also, but according to my mathematical calculations only thick nibs can be stably developed. thin nib for waterdrop design may be faced with long-term durability issues because of its slender design. but more studies are needed to 100% confirm this.

ultem barrel in the picture is just a slim symmetry barrel.

the nib was installed with masking tape, so this is just a test setup.

specific barrel and cap for the dip nib have to be developed in the future.

some notes about the development

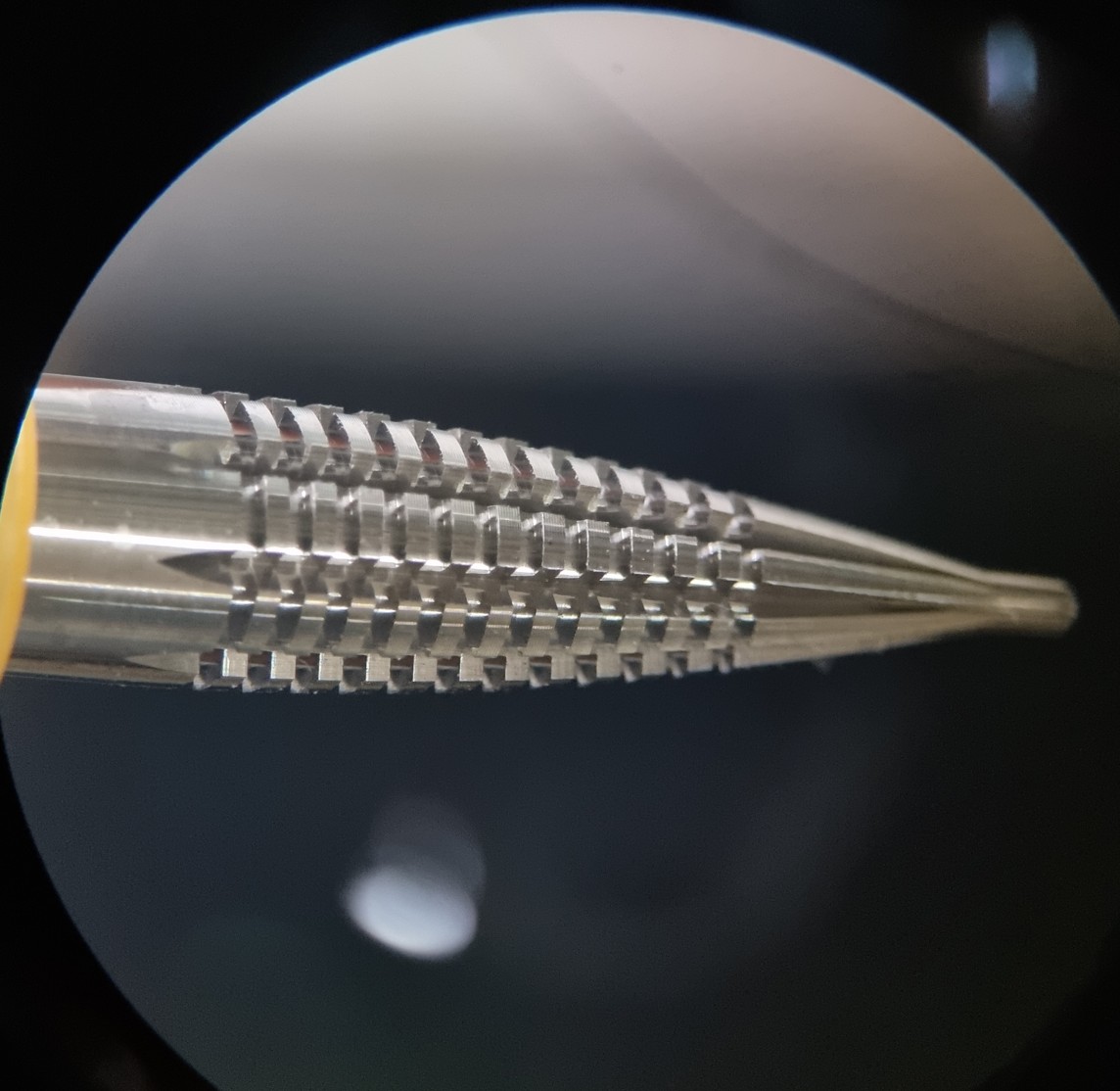

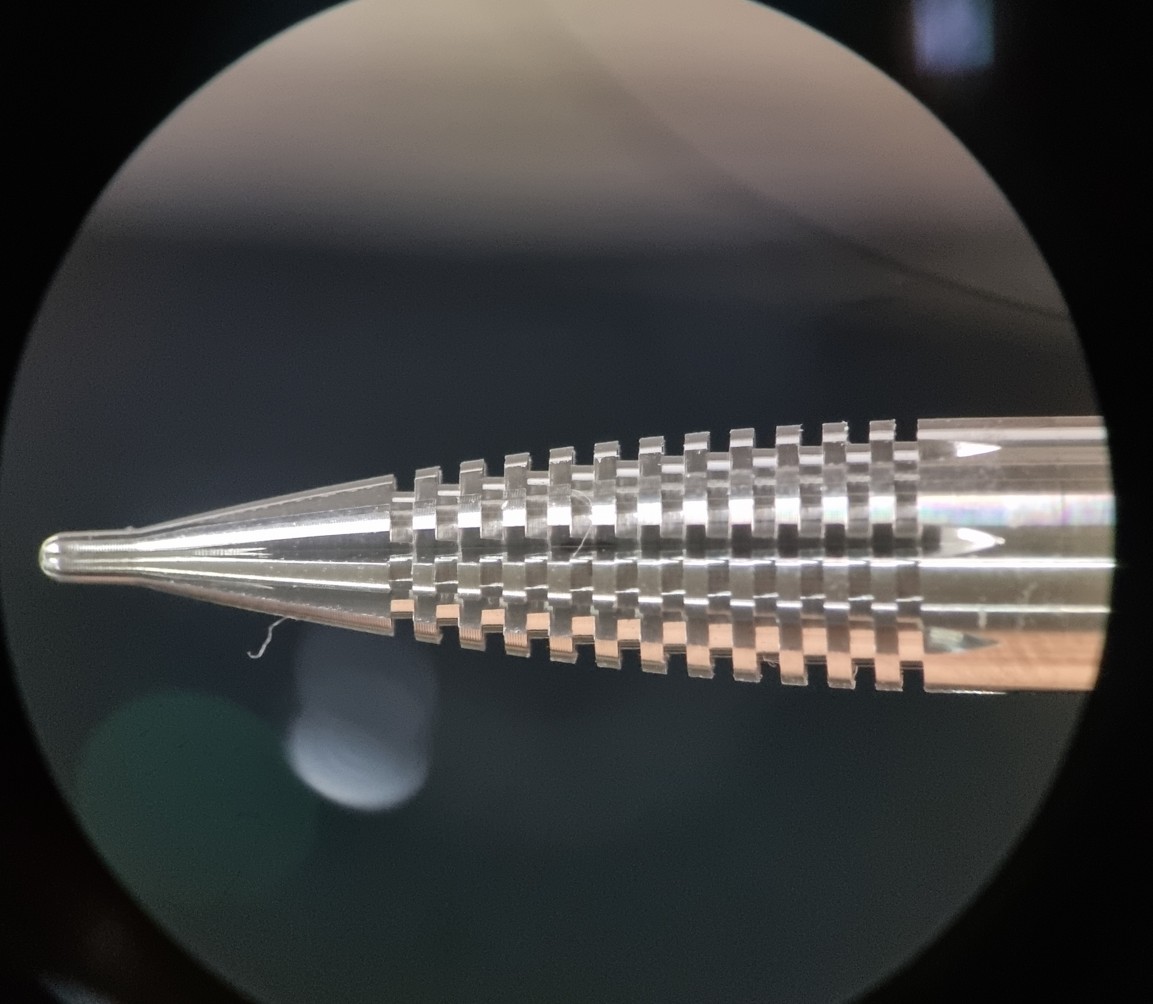

1. material: titanium grade23 (Germany)

2. there's 8 micro ink channels machined at the point area

3. microns level of accuracy needed to achieve the high level of machining perfection.

4. different versions of the nib was created, though some of them failed due to the high level of difficulty.

5. the nib point can be regrinded, but recommended only in a specific way (will be explained later @ online manual)

6. the dip nib type exhibits higher level of ink flow, compared to standard fountain pens. so high quality papers are recommended to write with.

7. initially production difficulty was greater than that of eureka titanium nibs. quite daunting to make the dip nib in titanium because of so many micro features.

8. polishing process may be applied (pictures below shows an example piece that hasn't gone through polishing process)

9. may apply coloring processes such as annodizing