*This manual will be updated periodically to include further information and refinements.

◆ Basic Detail Regarding the Nib

1) Material: Titanium alloy Grade 23 ( = Grade 5 ELI )

"Extra low interstitial" (ELI) refers to a grade of titanium alloy, specifically Ti-6Al-4V (Grade 5) ELI, where "ELI" stands for "Extra Low Interstitials". This designation indicates a version of the standard Ti-6Al-4V alloy with significantly reduced levels of interstitial elements like oxygen, nitrogen, and carbon.

The reduced interstitial content results in improved ductility, fracture toughness, and biocompatibility, making it suitable for demanding applications.

2) Material Origin: Germany or USA (will be specified on the each pen on sale)

3) Nib size: Vertical line M (0.6~0.7mm) / Horizontal line F (0.4~0.5mm)

4) titanium alloy hardness: approximately Moh 6~6.5

* typical "iridium-point" hardness: about Moh 6.5~7.5. Really hard ones estimated to be Moh 7.5+

* stainless steel = ~6 / iridium = 6.5 / osmium = 7 / tungsten = 7.5 / hardened steel = 7~8 / tungsten carbide = 9 / diamond = 10

5) this nib will spring back even if a large force is applied. the material has great returning properties, like a spring. Way more springy than typical gold or steel nibs that I experience.

* a very strong writing force is not recommend for this type of nib, because the tip is less hard than typical nib points.

* the ebonite feeder will provide ample amount of ink. Using the ink as lubricant and with light pressure, you will be able to glide the nib on the paper effortlessly. This will decrease friction and increase nib longevity.

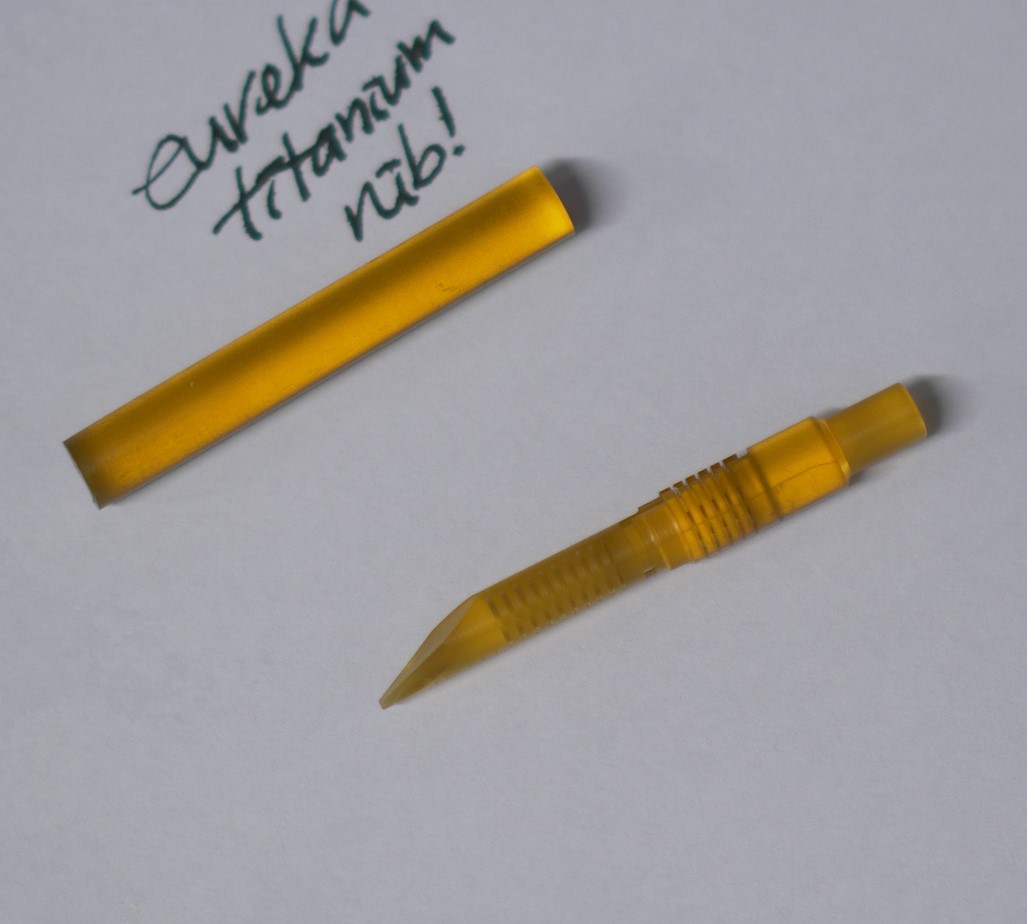

6) this nib is 100% precision-machined from a solid titanium rod

7) nib fixation method: thread-type. Easy disassembly, cleaning, and maintenence.

8) O-ring seal applied for the frontal grip area, so ink will not seap out between grip frontal hole area.

9) Nib - Feed assembly method: angular fixation + thread locking (precision within 0.05mm, appropriate tolerance for easy assembly)

10) nib hole / feeder OD tolerance 0.05mm (appropriate tolerance for easy assembly)

11) Ultem / Ebonite feeder precision (outer diameter) = ±0.01mm

12) a powerful surface hardening treatment applied

13) initially the nib point is grinded in such way slight resistance is felt. however this resistance will disappear as the pen is used. Initial taming of the point is faster than conventional nib point alloys. After initial taming the nib will become very smooth.

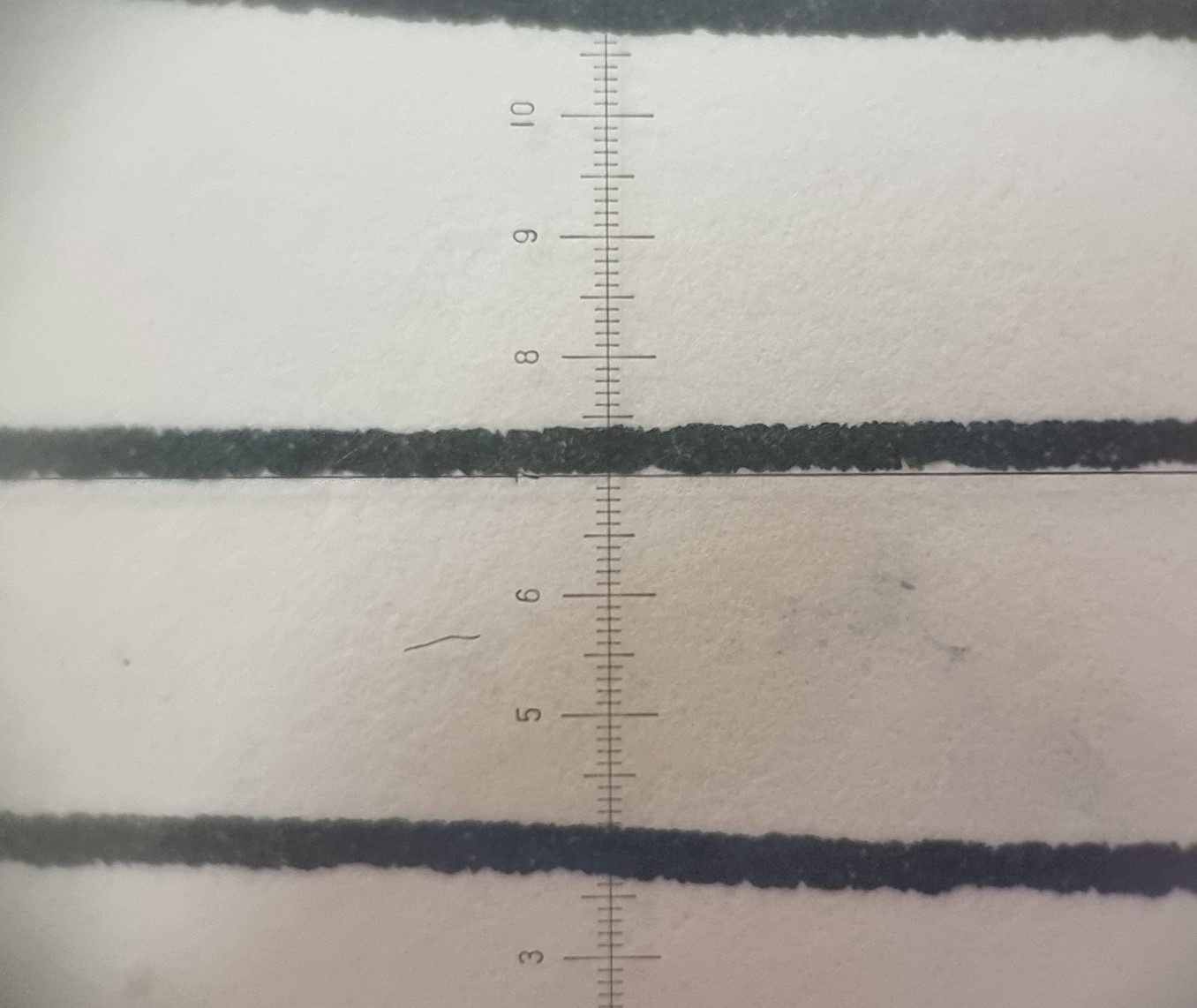

◆ Nib size: Vertical line M (0.6~0.7mm) / Horizontal line F (0.4~0.5mm)

Left: Vertical line thickness

Right: Horizontal line thickness

◆ Maximum effective nib point length = 5mm

1) because the titanium point is less hard than typical nib point alloys, the titanium point design is much elongated to maximize the nib longevity.

2) multiple regrind of the nib is possible by the user.

3) the user can grind the nib thickness and shape, if needed.

* it is less demanding to to grind than typical nib point alloys. so regrinding the nib point is relatively easier.

* do note that the titanium alloy is harder than stainless steel, so it may take some effort to grind the titanium.

◆ Feeder design optimized to maximize the effective nib point length (at 45 degrees).

Robust feeder design, so accidental breakage while disassembly is unlikely.

* when first filled with ink, initially ink flow may be unstable as the feeder is not fully wetted yet. But this should stabilize within several days, and full normalization(taming) could take longer.

Ebonite will naturally become hydrophlic (wettable), as the sulfur from the surface disappears and becomes porous. This naturally occuring porosification will take place on all surfaces exposed to air and ink, and complete taming requires much time. eventually outer surface, inside surface of the combs, air channel, and even the ink channel will become very hydrophilic.

* when first filled with ink, please point the nib upwards while carrying around to prevent any leakage.

after the feeder normalizes, this may not be necessary (except extreme circumstances).

initially developed ULTEM feeder (currently not on sale due to hydrophilicity issue, more research is needed to make it fully functional)

Instead of the ULTEM feeder, Ebonite feeder has been subsequently developed.

Considerable structure design changes are applied, compared to the ultem feeder.

All current models that uses titanium nib will be equipped with the ebonite feeder.

◆ The nib point is designed in such a way, so that the writing thickness will be even across all range of the nib point length.

* initially the thickness will be thin because the end of the point is rounded.

* as the round point wears down, the writing thickness will increase (unless a regrind is done).

◆ How to regrind the nib: to be updated

◆ How to smooth the nib point (It takes approximately 30 seconds for each of the left or right tines)

- sanding pad (sponge type), grit #2000~3000 recommended.

- do not use too fine abrasive, as too much polished nib point can cause skipping issues.

- If the nib feel a bit scratchy while writing: press with your index fingernail Left or Right tine (near the point) down a bit (*not too much). Then lightly grind the internal sharp areas with the sanding pad. Grind away the minimum amount as possible, checking often to see if the scratchiness is mostly gone. Must use circular motion of your wrist to create radius grind shape, instead of a linear / straight motion. Do not grind too much, as this can cause ink skipping.

- write on the paper and find rough spots. very lightly grind away the rough spots, using circular motion.

- If the nib skips, simply grind on the pad with a circular motion to reduce the baby bottom. This will wear down the nib a bit. If you grind too much, the nib will feel scratchy again. In this case you may have to repeat the above mentioned process.

◆ How to remove / install Nib & Feeder

see here: https://eurekafp.com/977

How to remove / install feeder (for titanium nib)

1. Rotate nib & feeder counterclockwise to disassemble from grip section. 2. released from the grip section 3. Pull the feeder out carefully (may require some force), give it a slight rotational wiggle if necessary.to install again, simply push in the feed

eurekafp.com

◆ methods of pen ink refill.

1st method: standard method of removing the cartridge and directly filling the cartridge with syringe / spoid.

2nd method (Recommended): after removing the titanium nib (open counterclockwise), directly filling into the grip section hole with syringe / spoid.

* when filling ink, you must aim at the inner wall and inject slowly. If you don't follow these, ink will not be able to flow down the wall, and ink will get stuck and spill out from the opening hole.

◆ Frequent installation / removal of the ebonite feeder can loosen up the friction fit.

If you'd like the nib / feeder to fit more tightly, you can apply thin & even layer of superglue to the under side of the 2 flat areas as indicated below.

*Only apply the glue after the feeder is removed from the nib (and completely dried).

Do not use the superglue bottle itself to apply the glue!

Put a drop of superglue elsewhere (ex. on wax paper, plastic, etc.)

Hold a blunt toothpick (blunt down with a sandpaper) vertically then dab on the drop of superglue, and evenly apply the glue on the 2 flat areas.

The super glue must be completely cured before fitting the nib and feeder together.

If too much is applied, the friction fit may be too tight.

in this case you may have to grind away the excess superglue with a sandpaper.

◆ writing test video

https://www.youtube.com/watch?v=yTHn1FBCksU